Belgium Steel Mill Maintains Efficient Coil Cooling System

Steel Mill Maintains Efficient Coil Cooling System with Lakos Separators

Immersing their hot coils in large tanks reduced the cooling process time for the Sidmar Steel Mill in Belgium from 6 hours to 30 minutes. To prevent an otherwise costly problem of mill scale build-up in their system’s heat exchanger, Sidmar chose the continuous filtration performance of two Lakos Industrial Code Separators. According to plant spokesmen, if the iron oxides and scale (created when the coils are dipped into the cooling tanks) were allowed to build-up in the tanks, frequent and costly system shutdowns for cleaning and excessive labor costs would have minimized the system’s efficiency and effectiveness.

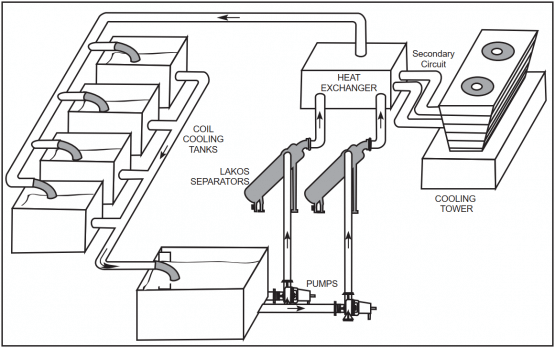

The computer-controlled system calls for the water in the cooling tanks to be displaced by cool water from their heat exchanger and transferred to a sump after it has reached a specified temperature (see diagram). Individual pumps then feed the water through the Lakos Separators at a combined rate of 8,800 U.S. GPM (2,000 m3/hr) and directly to the heat exchanger. Accumulated solids are purged automatically from the Lakos Separators at regular intervals, thereby requiring no routine maintenance whatsoever.