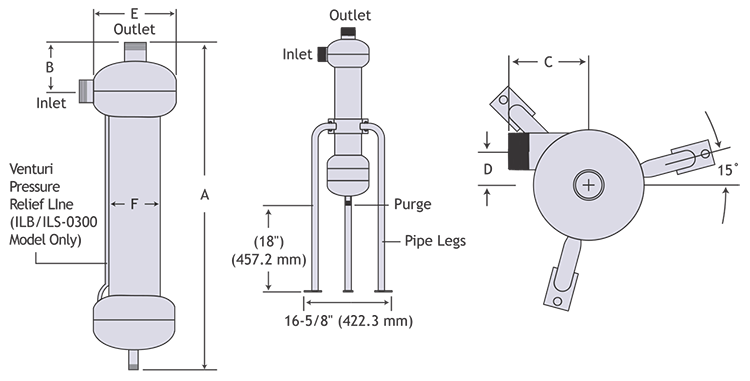

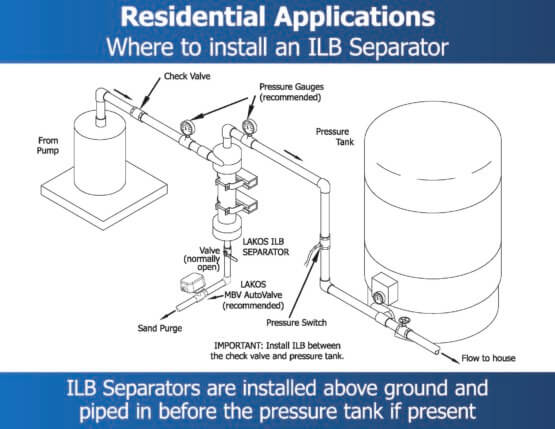

Ideally suited for smaller system applications, side-stream installations, and individual equipment protection. LAKOS ILB-ILS Centrifugal Separators are the popular choice for removing sand, grit, and other fine solids from sources of process water/liquid systems, removing up to 98% of particles 74 microns and larger. When used for heavier solids like metal shavings and lead chips you can expect even better results.

LAKOS ILB-ILS unique centrifugal style of filtration is not only super efficient, but also trouble-free in its design.

Flow Range: 3 – 290 US GPM (0.7 – 66 m³/hr)

Maximum Pressure: 150 psi (10.3 bar)

Features and Benefits:

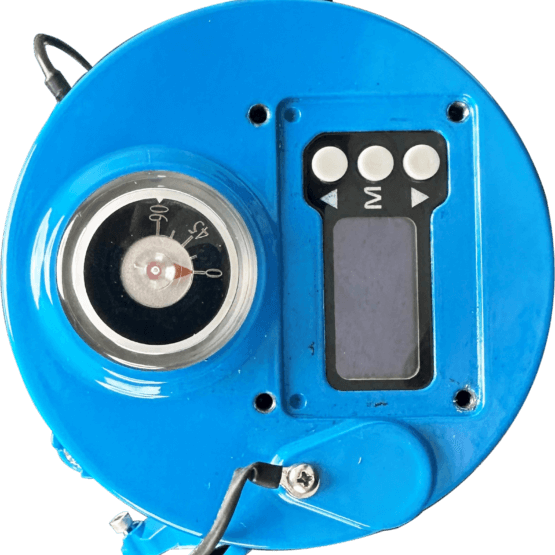

- No moving parts to wear out or replace

- No screens, cartridges, cones, or filter elements to clean or replace

- Centrifugal Separator patented technology

- Zero backflushing and downtime requirements

- Pressure loss as low as 5 psid

- Heavy duty construction, available in rugged carbon steel (Model ILB) or stainless steel (Model ILS)