*System Requires Use of eHB HydroBoosters

Cooling Water Filtration for Industrial Applications

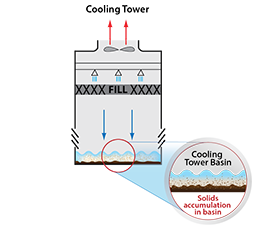

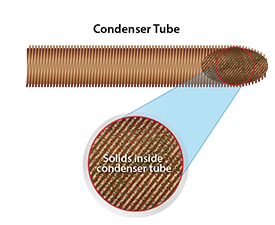

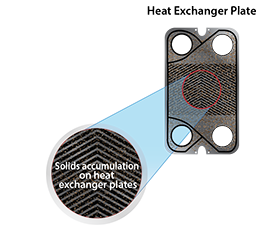

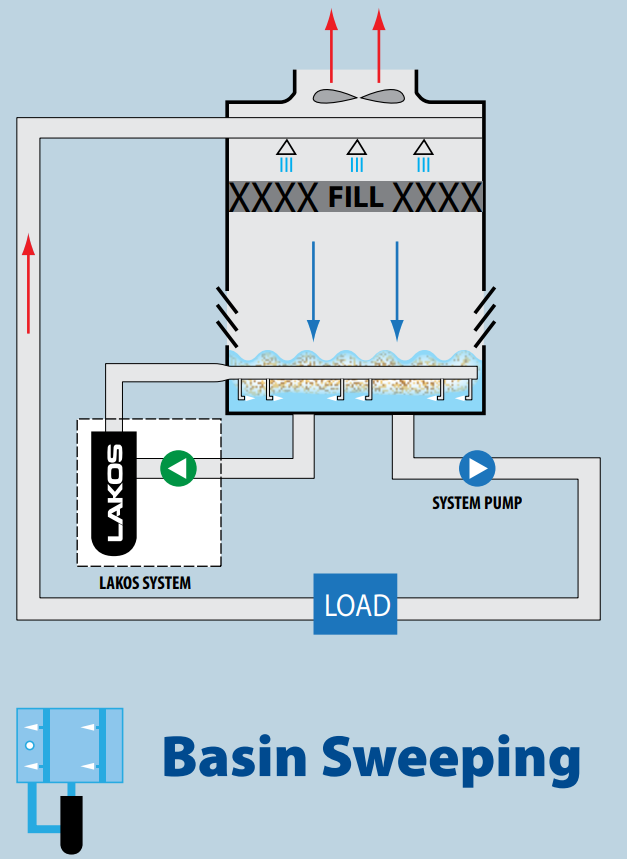

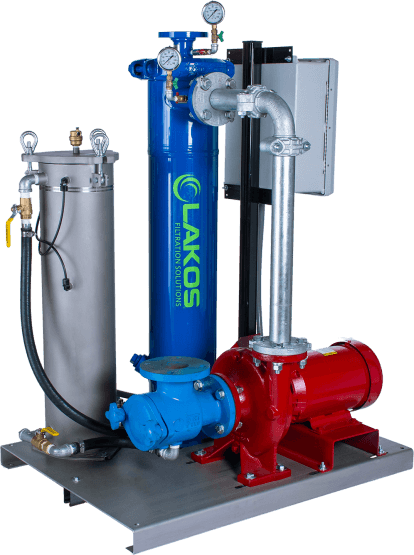

LAKOS eJCX Systems keep cooling tower basins free of suspended solids that cause scale, corrosion, fouling and biological activity. Controlling these factors leads to lower maintenance, improved chemical effectiveness, longer cooling tower and downstream equipment life, and a significant decrease in long-term water and energy costs.

- Premium Efficiency centrifugal filtration, independently tested, rated to remove up to 98% of solids 44 microns and larger in a single pass, and up to 99% of solids 25 microns and larger in recirculating applications.

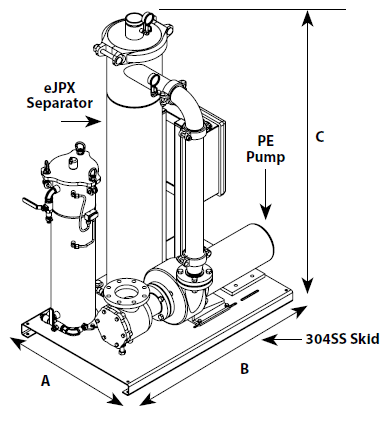

- eJCX Systems feature LAKOS eJPX Centrifugal Separator, Premium Efficiency pump, higher capacity (12 liters) Solids Recovery Vessel and/or Fail-Safe Automated Purge valve.

- Minimize tower nozzle clogging, protect basin floor from under-deposit corrosion, eliminate risk of injury associated with manual basin cleaning, and greatly reduce heat transfer loss in downstream equipment.

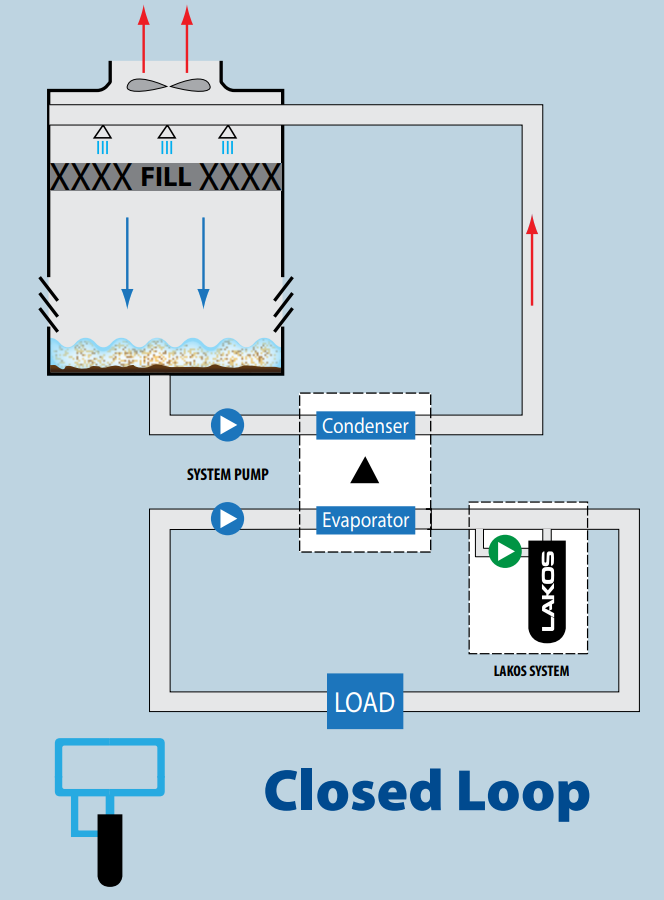

Basin Sweeping Flow Range: 110 – 1,110 US GPM (25 – 252 m3/hr)

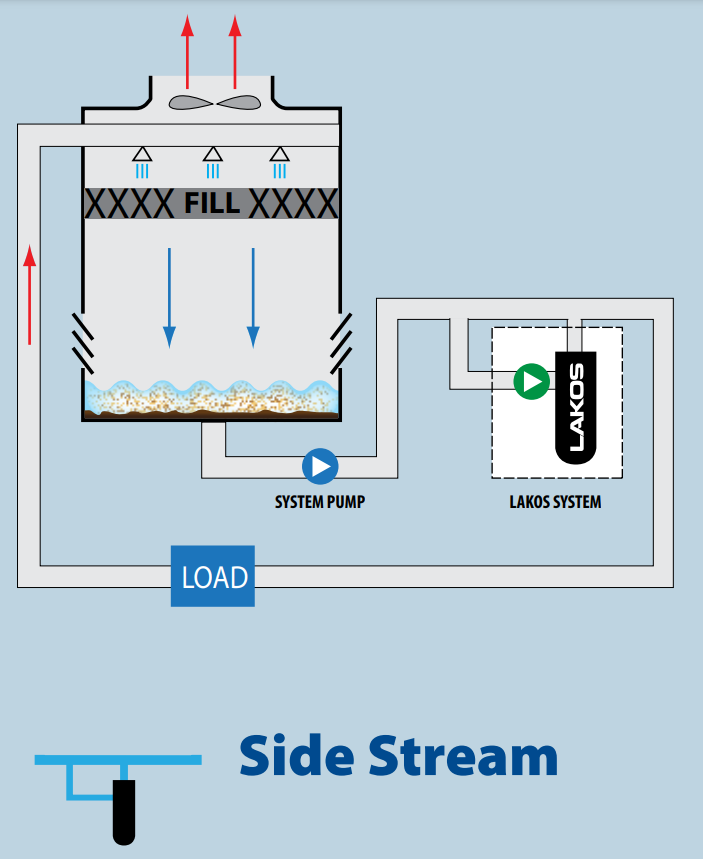

Side Stream Flow Range: 140 – 1,110 US GPM (32 – 252 m3/hr)

Filtration level: Removes fine solids 25 microns and larger