- Identify your wells inner diameter.

- Find your pump’s flow range.

- The best fit model is in the middle of the range. DO NOT OVERSIZE.

- Verify your wells depth, water level, and pump depth.

- Verify your pump and motors dimensions (length and width).

SUB-K Pump Protection Separators

Starting with protection at the source, you can expect increased pump efficiency, reduced sand wear and tear on pump components, and an overall reduction in energy consumption.

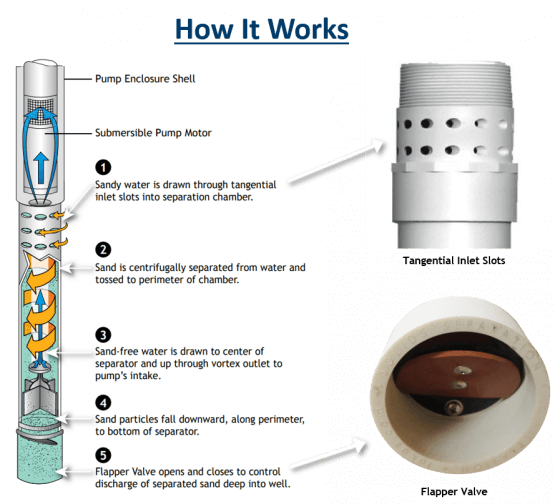

LAKOS Pump Protection Separators prevent sand from entering submersible or turbine pumps, by removing sand from well water through centrifugal action.

| Models | Minimum Well I.D. | Separator Length | Flow Range | Weight | ||||

| inches | mm | inches | mm | US GPM | m3/hr | lbs. | kg | |

| SUB-8-4-PAK | 4″ | 102 | 36.5″ | 927 | 3-8 | 0.7-1.8 | 9 | 4 |

| SUB-12-4-PAK | 4″ | 102 | 36.5″ | 927 | 5-12 | 1-3 | 9 | 4 |

| SUB-16-4-PAK | 4″ | 102 | 36.5″ | 927 | 10-16 | 2.5-3.8 | 9 | 4 |

| SUB-28-4-PAK | 4″ | 102 | 40.75″ | 1,035 | 14-28 | 3-6.5 | 11 | 5 |

| SUB-8-4.5-PAK | 4.5″ | 114 | 36.5″ | 927 | 3-8 | 0.7-1.8 | 9 | 4 |

| SUB-12-4.5-PAK | 4.5″ | 114 | 36.5″ | 927 | 5-12 | 1-3 | 9 | 4 |

| SUB-16-4.5-PAK | 4.5″ | 114 | 36.5″ | 927 | 10-16 | 2.5-3.8 | 9 | 4 |

| SUB-28-4.5-PAK | 4.5″ | 114 | 40.75″ | 1,035 | 14-28 | 3-6.5 | 11 | 5 |

| SUB-8-5-K | 5″ | 127 | 36.5″ | 927 | 3-8 | 0.7-1.8 | 12 | 5 |

| SUB-12-5-K | 5″ | 127 | 36.5″ | 927 | 5-12 | 1-3 | 12 | 5 |

| SUB-16-5-K | 5″ | 127 | 36.5″ | 927 | 10-16 | 2.5-3.5 | 12 | 5 |

| SUB-28-5-K | 5″ | 127 | 40.75″ | 1,035 | 14-28 | 3-6.5 | 15 | 7 |

| SUB-52-5-K | 5″ | 127 | 43.75″ | 1,111 | 24-52 | 5.5-12 | 20 | 9 |

| SUB-99-6-K | 6″ | 153 | 50″ | 1,270 | 48-99 | 11-22.5 | 23 | 10 |

Frequently Asked Questions

Answer: Solids-removal efficiency is affected by several factors, including the difference in specific gravity between the solids and the carrying liquid, the viscosity of the liquid, the particle shape, and any purging enhancement techniques. In general, with a specific gravity ratio of 2.6 (e.g. quartz sand in freshwater), liquids of 31 SSU viscosity, and generally round particles, a single pass through a separator predictably removes up to 98% of particles 74 microns (0.0029 inches) and larger.

Appreciable quantities of particles finer than 74 microns are also removed, as well as particles of lighter specific gravity. Higher specific gravities (like mill scale in water, where SG=5.7) result in much finer levels of filtration.

Contact LAKOS for assistance determining performance expectations on your specific application.

Answer: The maximum solids loading on LAKOS Separators is recommended to be less than 1% by volume. While 1% may seem low, keep in mind that 1% in a small 100 GPM system is 1 gallon of solids every minute, or 1,440 gallons (twenty-six 55-gallon drums) of solids per day. SMP Separators for residential use are not recommended to exceed 0.25% by volume. ILB Series Separators are not recommended to exceed 0.50% by volume. If your application exceeds these limitations, please consult your factory representative for proven alternatives.

Answer: The sand is discharged to the bottom of the well. Over time, the flow dynamics of the well formation are changed due to the accumulation of the sand, and water is pumped without disruption through the life of the well. In fact, in over 30 years of experience with PPS Separators, less than a handful of wells have ever needed to be bailed, and in those few cases, the benefits received from longer, more efficient pump life far outweighed the one time bailing.

SUB-K pump protection separators