Heat Exchangers and Heat Pumps

Stop scale, fouling, biological activity and corrosion

Solids in cooling tower water can clog channels and create areas of low thermal conductivity. Suspended solids reduce the heat transfer areas and decrease flow inside condenser tubes by accumulating on internal tube fins. For every .001″ increase in fouling, energy consumption increases by 11%. Put an end to clogging and fouling with heat transfer filtration solutions.

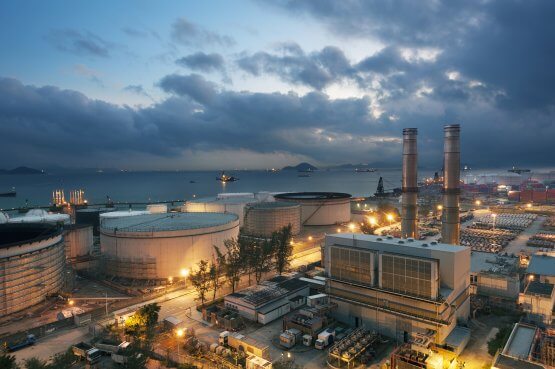

Electric Power Plant Reduces Fouling in Heat Exchanger & Condenser

A major east coast power plant had to remove their heat exchanger due to heavy sludge fouling every six to eight weeks to be mechanically cleaned, resulting in labor intensive maintenance and a loss of approximately $1,000,000/day per shutdown. In order to escape costly shutdowns and intensive maintenance, the power plant installed a LAKOS LAX Series Separator which caused the fouling to stop and even the most minimal maintenance and repairs were cancelled. Learn More

Heat Exchanger Protected by LAKOS Separator

Industrial Electric Heating Company of Columbus, Ohio manufacturers and sells metal parts and components that are hardened by heating to temperatures of 1600-1800 degrees. Through the heating and cooling process of these parts, slag particles can foul the system’s heat exchangers and clog quench tanks, pipes, and spray nozzles. Industrial Electric Heating Company soon installed a LAKOS In-Line Separator which allowed the removal of solids and helped to protect the heat exchanger and spray nozzles. Learn More

Heat Pump Distributor Eliminates Number One Problem: Sand

Brett Mattinson of Decker & Mattinson Co. of Hutchingson, Kansas was in need of protecting the water regulating valves on their groundwater heat pump installations due to large amounts of sand chewing up the valve seats which led to constant leaking by the valves. Mr. Mattinson decided to install a LAKOS Separator with every heat pump he installs, which helps save nearly $120,000 in parts and labor to replace the valve seats. Learn More

Heavy Equipment Manufacturer’s Heat Exchangers Become More Efficient

A Midwestern heavy equipment manufacturer struggled to find an effective filtration method from removing bag filters in their heat exchangers due to their constant clogging in the quench and descaling process. A LAKOS PRX System was installed and after two years the heat exchangers required no cleaning and saved this heavy equipment manufacturer over $83,000 annually. Learn More