Water Treatment System Removes Sand Without Downtime

Water Treatment System Removes Sand Without Downtime

System: River Water Intake, Pre-Filter to Water Treatment Plant

Solids: Suspended Sand Liquid: River Water

Problem/Challenge: Keep High Sand Concentrations Out of the Water Treatment System Without Requiring Downtime/Routine Maintenance

Solution: Nine LAKOS JPX Series Separators with AutoPurge

Problem: Consulting engineers for the Buckman Diversion Project were challenged to find a filter system capable of handling sand concentrations up to 550 ppm from the Rio Grande River near Santa Fe, New Mexico—without having significant downtime or maintenance routines. Traditional filters were considered, but due to the expected high sand concentrations in the water and the related servicing requirements for these filters, they were rejected. There was also the challenge of the location: since the pumps were located at a remote site, maintenance-free operation was a major goal.

Solution: Once engineers at CDM Engineering reviewed LAKOS Separators, with both their ability to handle large volumes of sand AND low maintenance operation, their search for a solution was over. They chose LAKOS JPX Separators with an automatic purging option to remove sand from the water as it was being pumped from the river to the water treatment plant.

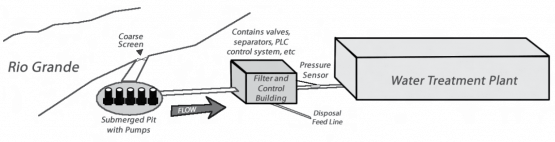

A coarse screen with air-jet cleaning capability is installed on the intake feed at the river to keep the very large debris from entering a submerged pit where five large variable-speed pumps push the water up from the river canyon to the water treatment plant. Located in a deep canyon, the water travels over two miles from the river to the distribution lines. The pump stations, filter and control building, as well as the water treatment plant are installed in a remote area, demanding that all of the equipment be relatively maintenance free and controllable via their PLC. Along the way, the 24-inch main line feeds water to as many as nine LAKOS Separators, each sized for a flow range of 1160 – 2150 US gpm. A pressure-sensing device downstream of the LAKOS Separators monitors line pressure and determines when to open or close electrically controlled valves, bringing any one or more of the separators into service to maintain proper flow through each separator. The automatic purge valves are programmed into a PLC-controlled system to monitor purging routines and allow remote control of the entire system. Separated sand is purged from the LAKOS Separators through a plug valve from each separator into a feed line for disposal.

Results: The construction of the Buckman Diversion project was managed through a joint venture of Western Summit Contractors and CH2M Hill Engineering. Upon completion, operation of the entire project was turned over to the City of Santa Fe who now monitor and oversee all operations. Up to 20 million gallons per day of treated water is delivered to the City of Santa Fe, the county of Santa Fe and a planned community project outside the city, through this 100% privately funded water project. Minimum staffing was a top goal of the project and the LAKOS Separators have been instrumental in achieving that goal.