Electronic Assembly Plant Saves Water & Valuable Solids

Separator Saves Water and Valuable Solids in Wet Scrubber Operations

Water consumption was cut by 90% and the recovery of solids matter alone paid back the cost of an installed Lakos Separator within a couple of weeks at Pixley Richards, Inc. of Plymouth, Massachusetts. Utilizing separators in several systems at this electronic subassembly plant, the overall operating efficiency is reportedly very, very much improved.

“We were cleaning out sumps and valves every couple of weeks,” said Ron Cook, Mechanization Engineer. “I can’t imagine operating without Lakos nowadays.”

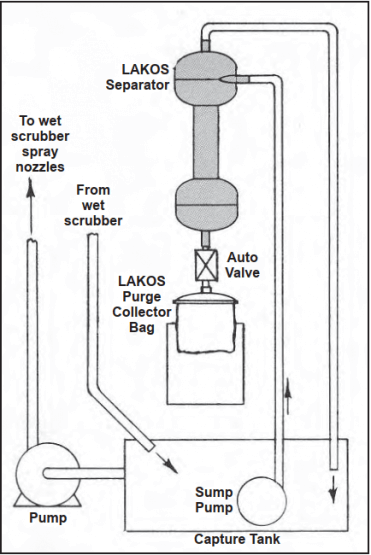

The recovered solids in one system is a poly blast media, .030” diameter in size, which is used in conjunction with water as a wet scrubber to neutralize excessive static electricity in their cabinet system for plastic deflashing operations. Water and media collect in a sump which is recirculated through the Lakos Separator to recapture the media. Water returned to the sump helps agitate and evacuate additional solids, while a second pump feeds water to spray nozzles in the wet-scrubber assembly.

Separated solids are purged automatically into a Lakos Purge Collector Bag, thereby recovering 90% of the poly blast media for re-use.

Coupled with other refinements in this area, the savings attributed to Lakos amount to a 70% reduction in maintenance. “That media costs us $4.00/lb.,” says Cook, “and we were losing as much as 44 lbs. each week. With Lakos, we’ve cut that expense by 90%.”