Cost Savings from LAKOS Basin Cleaning System

Cost Savings from LAKOS Basin Cleaning System

System : Two 1000 ton chillers and a cooling tower

Solids: Sand, silt, scale, calcium carbonate

Liquid: Water in open loop system at 825 gpm

Problem/Challenge: Reduce fouling in chillers to reduce energy costs

Solution: LAKOS TowerClean basin cleaning filtration system (TCX-0825)

Customers in Puerto Rico pay an average of $0.18Kw/hr to $0.19Kw/hr for commercial energy. In a manufacturing facility, chiller systems and other HVAC components are among the highest users of that energy, so it is critical to keep them running at their highest efficiency.

Effective filtration can keep the chiller tubes free from dirt and debris that foul tubes, and in turn waste energy. Perhaps the most effective form of filtration in these situations is to install cooling tower basin cleaning (“sweeping”) to prevent the accumulation of dirt, silt, scale and other contaminates in the system.

LAKOS cooling tower basin cleaning filtration systems can remove solids from cooling tower basins down to 45 microns.

A pharmaceutical company in Puerto Rico faced this challenging situation. They have two 1000 ton chillers operating 52 weeks a year, 24 hours per day. Operating at 70% of load, and 65% design efficiency costs $966,918 in energy at $0.185Kw/hr. Assuming the expected minimum 5 ppm in solids (per ASHRAE industry averages), it was calculated that removing these solids with a LAKOS Filtration System would result in annual energy savings of 10 percent or approximately $96,700 per year.

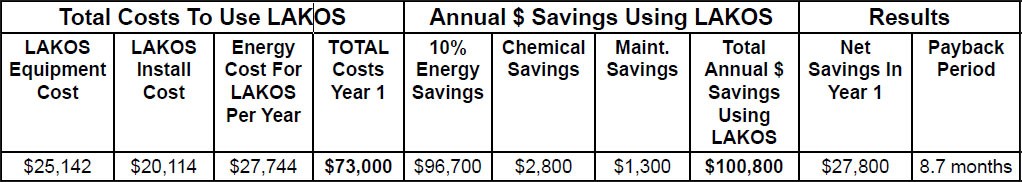

The company installed a LAKOS Basin Cleaning System (TCX-0825) for approximately $45,300 (equipment and installation). Energy cost to run the system for one year is expected to be approximately $27,744. Net savings in the first year should equal $23,700 and a return of investment in approximately 9 months. Add yearly savings on chemicals ($2800) and maintenance ($1300) and LAKOS filtration proves to be an excellent way to reduce high energy costs in chiller systems.

Savings and ROI

Results stated are based on input from the initial overall system engineering design parameters using the LAKOS ROI Calculator (return on investment estimator)to generate the values presented. The values may vary based on the final operating parameters.