Zebra Mussels Removed at Steel Piping Mill

Zebra Mussels Removed at Steel Piping Mill

Application: Custom JSK Separator At Steel Mill

Solids: Sand, Silt, Zebra Mussels

Liquid: Lake Michigan Water

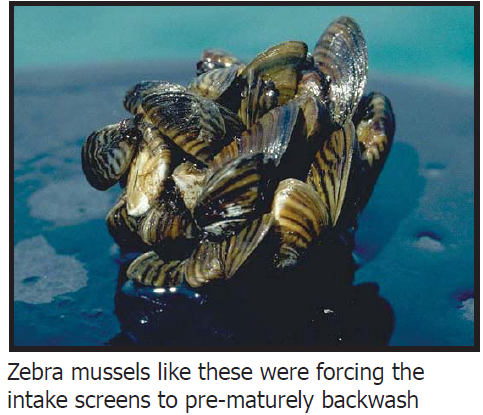

Problem: A very large steel manufacturer in northwestern Indiana already had several successful LAKOS solutions throughout their facility, but two problems still plagued the mill. The first issue was sand and silt in the water from Lake Michigan. The dirty lake water was drawn downstream to very costly pumps, which are used to feed high pressure water to de-scaling nozzles. Keeping the pumps at peak performance is critical to making sure that the high pressure spray nozzles fully perform as designed, allowing the steel to meet the high standards of the automobile and appliance industries for whom the steel is manufactured. The second issue was zebra mussels attaching themselves to the piping that feeds the pumps and the self-cleaning screens that were being used to protect the pumps. These harmful mussels form a consistency equal to concrete, causing the self-cleaning screens to experience a drop in pressure, forcing them into premature back-washing cycles. The problem was so bad, it forced the facility to by-pass the screens all together, which in turn caused problems with the pumps and spray nozzles. Because of their previous success with LAKOS products, the steel plant knew who to turn to solve these problems.

Solution: LAKOS and the local distributor worked with the on site mechanical engineer and came up with a solution for protecting the pump and preventing zebra mussel buildup. A custom model JSK-2650-L/FLG was designed using a special, all natural and environmentally safe interior coating that did not allow the zebra mussels to attach themselves to the separator. Within the first month of the installation, the mill was convinced of the efficiency of the separator.

The mechanical engineer in charge of the project was extremely happy with the amount of sand and silt that the JSK was removing, as well as the fact that the zebra mussels were not affecting the filtration performance. The mussels and sand from the lake were no longer negatively affecting the separator, unlike on the screen fi lters that had previously failed because of their blockage. He was not surprised by the outstanding performance, however, because of his previous experiences with LAKOS products.“I do not have to worry about who is going to service the LAKOS Separator, or having to by-pass the unit, causing me other issues downstream,” said the engineer.

The LAKOS JSK shows a huge return on investment factor for this application. The cost of repairing a high pressure pump in a de-scaling operation can be upwards of $150,000. Removing the sand and silt to protect the pump can extend a repair schedule on the pump from every year to every three to four years. If the separator is conservatively calculated to double the pump life before repair, the unit pays for itself in just six months time!

“When we install a LAKOS Separator, we know that we will not have to address issues with maintenance and we do not have to keep costly parts on hand as we do with self-cleaning screens,” said the mill’s mechanical engineer,“This makes a HUGE difference.”