When sand and dirt gets inside your homes water supply it restricts flow, clogs faucets, showerheads, damages ice makers, water dispensers, and plugs sprinkler heads. The conventional solution is to install sediment filters that use cartridges to remove sand and dirt. However, you are then stuck with changing cartridges every so often and replacing cartridges or filters can get expensive and tiring.

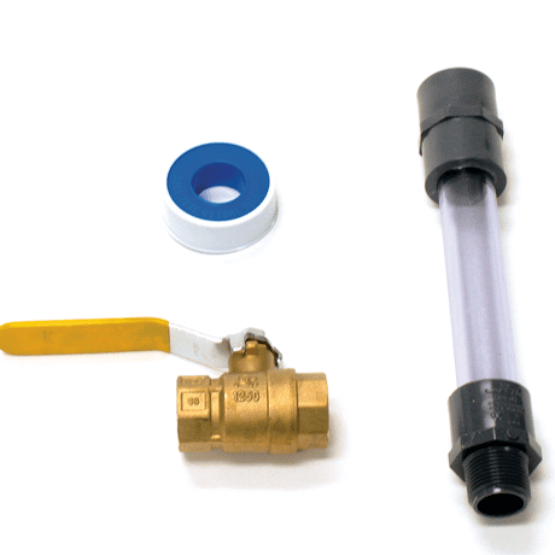

The easy solution to removing sand and dirt is to install a LAKOS SandMaster Separator. These NSF certified residential separators remove sand and dirt continuously with no moving parts, cartridges to change, or screens to clean. An SMP equipped with an automated purge valve flushes sand out of the separator automatically; Zero maintenance!

By installing a SandMaster Separator you not only remove dirt and debris from you water, but also extend the life of other water filtration equipment around the house. For example, if you have a Reverse Osmosis (RO) under-the-sink water filter or fridge water filter… the Separator will remove the dirt and debris from your water so that the filters can focus on removing the finer dissolved solids only. Thus extending their life and maintaining design efficiencies for longer periods of time.