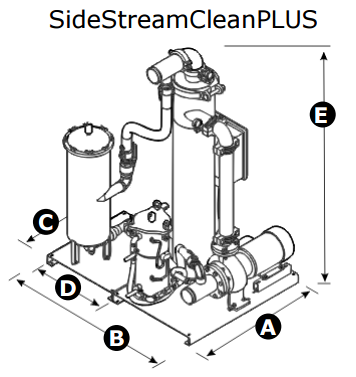

SideStreamClean PLUS Packaged System for Sub-Micron Filtration

The LAKOS SPX Systems take a standard TBX System and pairs it with a LAKOS Cartridge Filter to create a SideStreamClean PLUS System. The SideStreamClean PLUS System takes a portion of liquid from the outflow that has already gone through the LAKOS Separator and filters it through a cartridge filter for even finer or sub-micron filtration.

Flow Range: 65 – 1,100 US GPM (15 – 250 m³/hr)

Maximum Pressure: 150 psi (10.3 bar)

Cartridge Filter Micron Ratings: 0.35, 1, 5, & 10 microns