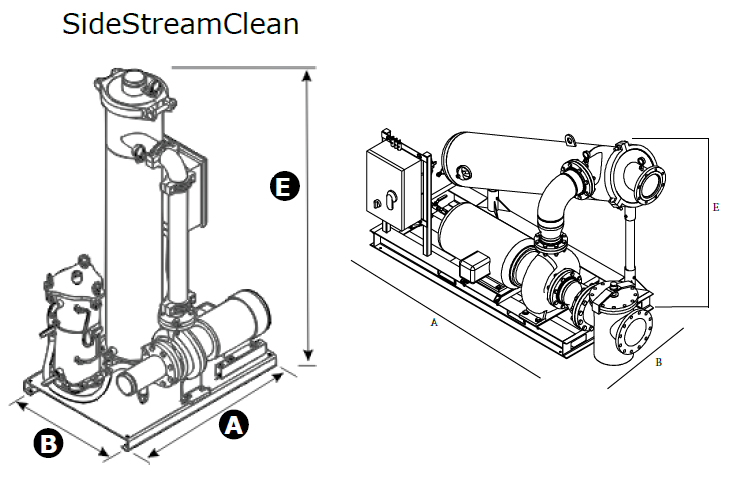

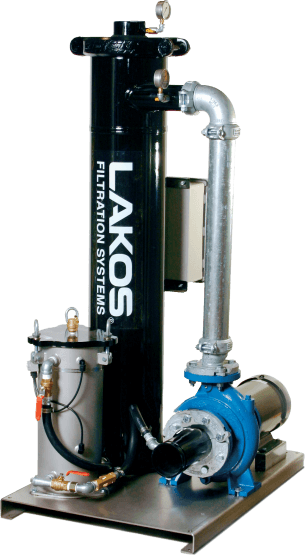

Packaged Separator Systems for Side Stream Condenser, Chilled & Hot Water Applications

Flow Range: 30 – 1,670 U.S. GPM (7 – 379 m³/hr)

Maximum Pressure: 150 psi (10.3 bar)

- Filter performance rated to remove up to 98% of solids, 74 microns and larger, and up to 99% of solids 45 microns and larger in recirculating applications.

- TBX/TBI Systems include a Lakos High-Efficiency Separator, High-Efficiency pump, standard capacity (6 liters) Solids Collection Vessel and/or Automated Purge valve.

- TBX/TBI systems are designed with low head pumps for Side Stream applications.

Our high-efficiency Side Stream filtration system removes fine solids* (44 microns and larger) from HVAC open and closed loops. This packaged system reduces equipment operating costs, maintenance costs, and water use. The ideal option in cases where side stream filtration is preferred.

* 2.6 specific gravity and heavier